Technical Information

When a male half quick disconnect and female half quick disconnect are connected together, it forms what is called a quick disconnect coupling assembly.

The male half and the female half each contain a spring loaded poppet valve. When the male half and female half are connected, the poppet valve opens allowing fluid or gas to flow in either direction.

When the male half and female half are disconnected from each other each poppet valve closes. Instantly stopping flow in both directions thus preventing fluid loss and air inclusion into the system.

Venting, bleeding, and replacement of fluid or gas lines can be expensive and time consuming. Using a quick disconnect coupling assembly is the best way to improve the speed and efficiency when working with a hose assembly in gas or fluid system.

Quick disconnects take the place of traditional fittings when fast maintenance, quick repairs, and easy replacement of are a necessity. The main benefit of using self sealing quick disconnects is the user can speed up inspection, maintenance time and/or replacement time without having to vent the system to the atmosphere.

Coupling Assembly

The self-sealing quick disconnect coupling assembly consists of a coupling half (female half) and a nipple half (male half). Each half instantly seals upon disconnection and instantly opens to flow upon connection. The coupling half (female) typically connects to a hose assembly. The nipple half (male) most often attaches to a pump, bulkhead, or reservoir.

Push-Pull Design

All sizes feature the "push-pull" design. This feature means all sizes of the quick disconnect couplings are easily connected and disconnected. Even the largest sizes do not require mechanical assists to connect. You can disconnect the assembly under far higher pressures than required by AS25427.

Versatility

SAF-T-FLO quick disconnect couplings can easily be modified to meet almost any operating requirement. When positive, non interchange of couplings is mandatory, the quick disconnect couplings can be supplied with "keys" to assure preferential mating and eliminate cross connection.

- Sizes: -4,-6,-8,-10,-12,-16,-20

- Available in Stainless Steel, Aluminum, or Titanium materials of construction.

- Valve stem for the coupling and nipple unit features a bonded elastomeric seal.

- "Grip Lock" Locking System

- Mil Spec. seal compounds for all fluid systems, including hydraulic fluids, jet fuels, lubricant, and coolants.

- Class 600 (Aluminum) and Class 3,000 (Stainless Steel) pressure ratings

- Self Aligning, Push-Pull Design

- Dust Caps for Male Couplings

- Pressure Cap for Male Coupling

- Dust Plug for Female Coupling

- Special "keys" for preferential mating

- Special "locking feature" to prevent unwanted release

All sizes of SAF-T-FLO quick disconnect couplings meet the requirements of AS25427, class 600 (600 psi) and class 3000 (3,000 psi) for hydraulic, self-sealing, quick disconnect. Performance requirements include the following:

- Hand Operation

- Extreme Temperature Functioning

- Proof Pressure

- Leakage

- Pressure Drop

- Air Inclusion

- Impact

- Vacuum

- Surge Flow

- Impulse & Vibration

- Endurance

- Manual Operation

- Burst Pressure

- Flange Strength

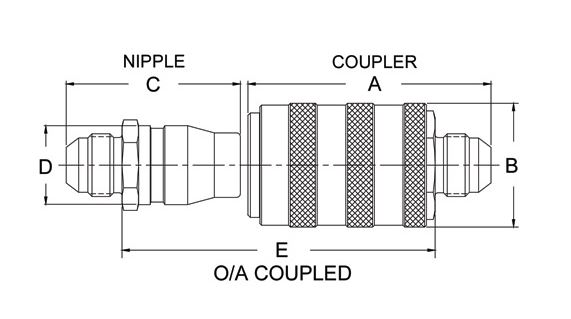

| size | a | b | c | d | e |

|---|---|---|---|---|---|

| -4 | 1.60 | 1.00 | 1.12 | .52 | 1.84 |

| -8 | 2.25 | 1.50 | 1.28 | .94 | 2.52 |

| -12 | 2.65 | 2.00 | 1.78 | 1.40 | 3.10 |

| -16 | 3.48 | 2.56 | 2.04 | 1.88 | 3.97 |

| size | a | b | c | d | e |

|---|---|---|---|---|---|

| -4 | 1.60 | 1.00 | 1.12 | .52 | 1.84 |

| -8 | 2.25 | 1.50 | 1.28 | .94 | 2.52 |

| -12 | 2.65 | 2.00 | 1.78 | 1.40 | 3.10 |

| -16 | 3.48 | 2.56 | 2.04 | 1.88 | 3.97 |

A self-sealing quick disconnect coupling assembly consists of two halves, a male half quick disconnect and female half quick disconnect. In most situations, the male half quick disconnect will attach to a bulkhead, reservoir, or tank. The female half quick disconnect will attach to a hose assembly or piping system.

The female half quick disconnect easily releases from the male half quick disconnect. With one hand on the female half quick disconnect, simply pull "back" on the outer ring. The female half quick disconnect will immediately release from the male half quick disconnect.